Views: 1 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

To cut rapid prototyping costs most effectively, 3D printing often leads for complex, low-volume designs due to minimal tooling and quick iterations, while vacuum casting excels for small batches needing injection-molded quality. CNC machining becomes cost-efficient for high-precision, functional parts made from production materials. The optimal method depends on your prototype's complexity, material needs, and required volume, ensuring cost savings without compromising quality.

In the competitive landscape of product development, managing costs is as crucial as innovation. Prototyping, while essential, can quickly become a significant expense if the wrong method is chosen. This article dives into various rapid prototyping techniques, analyzing which methods offer the most significant cost savings under specific conditions, helping you make informed decisions to optimize your budget without sacrificing quality or speed.

When is CNC Machining the Most Cost-Effective Prototyping Method?

How Does Vacuum Casting Offer Cost Savings for Small Batches?

What Role Does Rapid Injection Molding Play in Cost Reduction?

How Does Sheet Metal Fabrication Optimize Costs for Metal Prototypes?

Which Method Cuts Prototype Costs Most Effectively for Your Project?

Rapid prototyping costs are primarily influenced by material selection, part complexity, required precision, chosen manufacturing method, and the number of iterations needed. Understanding these factors is crucial for making informed decisions that optimize your budget while achieving desired prototype quality and functionality.

Material Selection: High-performance or exotic materials increase cost.

Part Complexity: Intricate designs demand more machine time and post-processing.

Required Precision & Surface Finish: Tighter tolerances and smoother finishes add expense.

Manufacturing Method: Each technology has different operational and setup costs.

Number of Iterations & Volume: Each prototype costs money; small batches can be optimized.

Post-Processing: Finishing services like painting or polishing add to the final cost.

For example, a medical device prototype needing biocompatible PEEK and tight tolerances will be more expensive than a simple ABS plastic enclosure.

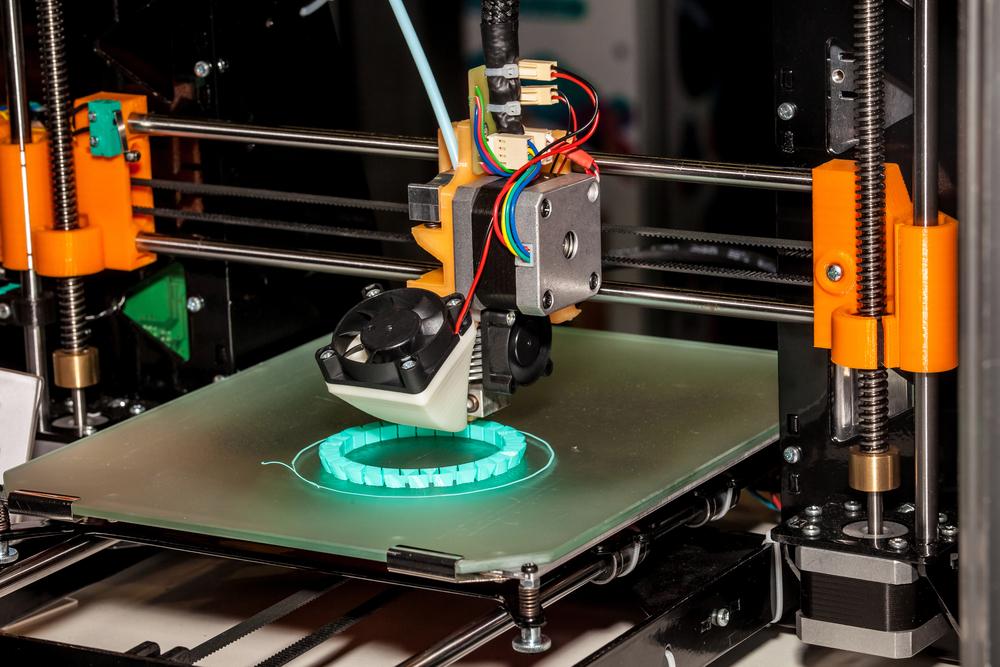

3D printing significantly reduces prototype costs by eliminating expensive tooling, minimizing material waste, and enabling rapid, cost-effective design iterations, making it ideal for complex geometries and early-stage validation. This additive process allows for quick production of intricate parts in as little as 4-6 days, optimizing budget for low-volume needs.

No Tooling Required: Builds directly from CAD, eliminating molds or fixtures.

Minimal Material Waste: Uses only necessary material, reducing scrap.

Design Complexity at No Extra Cost: Intricate shapes cost no more than simple ones.

Rapid Iteration Cycle: Quick turnaround (4-6 days) for multiple design changes.

Consolidation of Parts: Combines multiple components into a single print.

When 3D Printing is Most Cost-Effective:

Early-stage design validation (concept models, form/fit checks).

Complex geometries (internal features, organic shapes).

Low-volume or single prototypes.

Lightweighting designs.

For instance, a smartphone case with complex internal ribbing benefits from 3D printing for rapid, affordable design iterations and fit testing.

CNC machining becomes the most cost-effective rapid prototyping method when high precision, superior surface finish, and the use of production-grade materials are critical for functional testing, especially for parts with simpler geometries or in low-volume production runs. It delivers durable, high-quality prototypes in as little as 1 day, optimizing costs by ensuring accurate functional validation early on.

Production-Grade Materials: Uses actual final product materials for accurate testing.

High Precision & Tight Tolerances: Achieves superior dimensional accuracy (±0.001 inches), reducing rework.

Superior Surface Finish: Often produces production-ready surfaces directly, minimizing post-processing.

Simpler Geometries: Highly efficient for parts with flat surfaces, holes, and defined features.

Low-Volume Production: Cost-effective for batches from a few units to several hundred.

Durability & Strength: Creates strong, isotropic parts for rigorous testing.

When CNC Machining Offers the Best Value:

Functional prototypes requiring production materials (e.g., aluminum automotive parts).

Parts with critical tolerances (e.g., medical device components).

Prototypes needing a high-quality surface finish.

Low-volume manufacturing where injection molding tooling is too expensive.

An industrial equipment manufacturer testing a new stainless steel gear housing would find CNC machining most cost-effective for precise, durable prototypes.

Vacuum casting provides significant cost savings for small batches (up to 20-50 units) of high-quality plastic prototypes by utilizing inexpensive silicone molds, eliminating the need for costly hard tooling. This method delivers injection-molded-quality parts with excellent detail and surface finish in as little as 15 days, making it ideal for functional testing, market trials, or proof-of-concept models.

Inexpensive Tooling: Silicone molds are much cheaper and faster to create than hard tooling.

Low Setup Costs: Minimal machine setup compared to injection molding.

High-Quality Replicas: Produces parts with appearance and texture similar to injection molding.

Material Versatility: Can cast various polyurethane resins to mimic plastics.

Rapid Turnaround: Up to 20 parts in 15 days or less.

When Vacuum Casting is Most Cost-Effective:

Small production runs (20-50 parts).

Market testing and user feedback.

Functional prototypes with aesthetic requirements.

Proof-of-concept models.

A startup needing 10-20 units for beta testing a new consumer gadget would use vacuum casting for affordable, high-quality prototypes.

Rapid injection molding reduces prototype costs by offering a cost-effective bridge to mass production, utilizing simplified tooling (often aluminum) to produce engineering-grade plastic parts with near-production quality in as little as 5 days for expedited options. This method is ideal for structural verification and pilot-run batches, optimizing costs by validating designs with production-intent parts before committing to expensive steel molds.

Simplified Tooling: Uses aluminum or softer steel molds, cheaper and faster to machine.

Production-Grade Materials: Uses a wide range of thermoplastic resins identical to mass production.

High Repeatability: Produces consistent, identical parts for pilot runs.

Fast Turnaround: Expedited options as short as 5 days.

Scalability: Molds can often be adapted for higher volumes.

When Rapid Injection Molding is Most Cost-Effective:

Structural verification.

Pilot runs and small-batch production (hundreds to thousands).

Market validation with production-quality parts.

Bridging to mass production.

An automotive team needing hundreds of units for crash testing would use rapid injection molding for cost-effective, production-accurate plastic parts.

Rapid sheet metal fabrication optimizes costs for metal prototypes by offering a fast, efficient, and tooling-free process for creating durable metal parts from various materials in as little as 1-2 business days. This method is ideal for enclosures, brackets, and structural components, cutting costs by enabling quick design iterations and avoiding expensive hard tooling for low volumes.

No Hard Tooling: Uses digital files for cutting and bending, eliminating expensive dies.

Material Efficiency: Optimized nesting minimizes waste.

Fast Turnaround: Prototypes delivered in 1-2 business days.

Design Flexibility: Easy to modify designs digitally for quick iterations.

Wide Material Range: Works with aluminum, stainless steel, copper alloys, etc.

When Sheet Metal Fabrication is Most Cost-Effective:

Enclosures and housings (electronic devices, industrial equipment).

Brackets and structural components.

Flat parts with bends.

Low-volume metal parts (single prototype to several hundred units).

A robotics developer needing a custom aluminum chassis would find rapid sheet metal fabrication highly cost-effective for quick design, testing, and iteration.

The most effective method for cutting prototype costs depends entirely on your project's specific requirements: 3D printing for complex, low-volume designs; CNC machining for high-precision, production-material parts; vacuum casting for small batches of injection-molded quality; rapid injection molding for pilot runs; and sheet metal for durable metal components. A tailored approach, considering complexity, material, volume, and purpose, ensures optimal cost savings.

To truly cut prototype costs, match the method to your project's needs:

Prototyping Need | Most Cost-Effective Method(s) | Key Cost-Saving Reason |

Early Concept, Complex Geometry, Low Volume | 3D Printing | No tooling, minimal waste, rapid iteration. |

High Precision, Production Material, Functional Test | CNC Machining | Accurate testing prevents costly redesigns. |

Small Batch (20-50 units), Injection-Molded Quality | Vacuum Casting | Inexpensive silicone molds, high-quality replicas. |

Pilot Run (hundreds-thousands), Production-Grade Plastic | Rapid Injection Molding | Simplified tooling, production materials, high repeatability. |

Durable Metal Enclosures/Brackets, Low Volume | Rapid Sheet Metal Fabrication | No hard tooling, material efficiency, fast turnaround. |

Practical Steps to Optimize Prototyping Costs:

Define Purpose: What do you need to test?

Assess Complexity: Simple vs. intricate geometry.

Consider Material: Production material critical or not?

Determine Volume: Single unit, small batch, or pilot run?

Plan Iterations: Choose methods allowing quick, affordable changes.

Leverage Expertise: Consult with suppliers like KAIAO Rapid Manufacturing for optimal advice.

For a single, complex prototype, 3D printing is often the cheapest method due to no tooling costs and its ability to handle intricate geometries without additional expense.

CNC machining becomes more cost-effective when you need high precision, superior surface finish, production-grade materials for functional testing, or for simpler geometries, especially for low-volume production runs (tens to hundreds of parts).

Yes, vacuum casting can produce small batches (20-50 units) of injection-molded-quality plastic parts using inexpensive silicone molds. For slightly higher volumes (hundreds to thousands) with production-grade plastics, rapid injection molding with simplified tooling is a cost-effective bridge.

Lead times vary by method: CNC machining can deliver parts in as little as 1 day, rapid sheet metal fabrication in 1-2 business days, and 3D printing typically in 4-6 days. Vacuum casting usually takes around 15 days for a batch.

Post-processing (sanding, polishing, painting, etc.) is often an additional cost. The extent of post-processing needed depends on the chosen method and your desired surface finish. CNC machining often requires less post-processing for a smooth finish compared to some 3D printing methods.

Effectively cutting prototype costs is a strategic imperative. 3D printing excels for complex, low-volume designs and early validation. CNC machining is cost-effective for high-precision, production-grade functional parts. Vacuum casting offers quality and affordability for small batches, while rapid injection molding bridges to mass production for pilot runs. Finally, rapid sheet metal fabrication provides an efficient solution for durable metal components. By aligning your project's specific needs with the right prototyping method, you can optimize your budget, accelerate development, and bring innovative products to market efficiently.